Canmore entrepreneurs tackle the ski industry, one ski build at a time

By James Rose. Photos by Mike Stevenson

Zuckerberg, Jobs, Spiegel. Internet entrepreneur names you likely recognise as visionaries who have shaped our current lives. How about Max Flowerday and Sam McEwan?

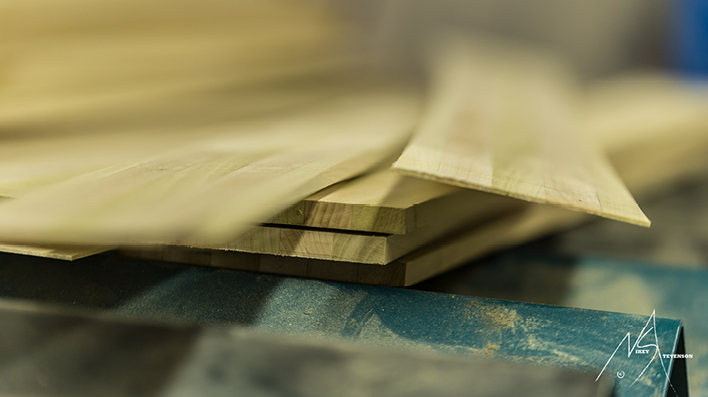

These two Alberta-based ski industry entrepreneurs, who traded in their high-paying oil and gas jobs to enter the hand-crafted ski manufacturing business, are learning the ropes of an emerging trend of building and selling skis in an effort to improve ski technology and performance.

What initially started as a weekend hobby, the two mechanical engineering graduates fuelled by a deep passion for all things skiing started a unique garage operation (they have since moved into shop space) of making handcrafted skis. The result? 93 North Skis; an independent ski manufacturing company, fittingly headquartered in the outdoor mecca of Canmore, Alberta.

“The first time that we thought about making skis was while on a ski tour at Bow Summit

Ten months later, the two crafted their first pair of skis and shortly after that, were open for business. “In the beginning, we did not consider ski manufacturing to be a potential career. There were so many unknowns and we were just excited to ski on something that we had made,” comments Flowerday.

The ski industry today is mostly dominated by a handful of major manufacturers. But forums and material-based sites, like skibuilders.com and skilab.com, guide ski enthusiasts on the knowledge needed to make skis.

“Before these forums were established it would have been very daunting to figure out the basics of ski manufacturing,” says McEwan. “But online resources can only get you so far. Since our first pair of skis, we have had to do a lot of problem-solving to get our product to where it is now. Sometimes things just don’t work out but we have done a good job of staying positive and learning from our mistakes.”

With the abundance of free information on the web, perhaps it should come as no surprise that more and more independent ski makers are popping up in both Canada and the United States, like Skevic, Foon, and Big Bend Skis. “We happen to be the only ski manufacturer in Alberta which may give us a bit of an advantage in the local market,” says Flowerday.

Independent companies in the U.S. – such as 4frnt, Moment, ON3P and Icelantic – have each been very successful. “All of this activity indicates to me that there is a movement going on, but having said that the big brands such as Rossignol and Volkl still make great products,” Flowerday says.

How then does an upstart like 93 North compete with behemoths like Rossignol? The low-hanging fruit at the moment seems to be building skis that are more in tune with local ski conditions; a regional bespoke approach.

“With the variable conditions present in the [Canadian] Rockies, it is hard to choose the right ski,” says Max. “Many skiers end up with two to three pairs of skis, one for powder, one for bulletproof ice and then something for everything in between.”

And thus was the impetus for what would become their first commercial ski: the Andromeda. The Andromeda first came to market in December 2016 and was designed to tackle everything from crud to deep powder. Priced at $795 per pair, the two founders feel that it’s a price point competitive for the market they are targeting.

“This ski is a go-getter and the carbon fibre reinforced poplar/maple core is designed specifically to charge through ice and crud,” says McEwan. The ski is available for sale from their shop or online. “Eventually we would like to get our skis in retail outlets but that will take some time.”

Yet for 93 North, the question that still remains is whether crafting skis for local conditions serves a big enough market to sustain a viable business. “People respond very positively when they find out that our skis are handmade in Canmore,” says Flowerday. “Our skis perform very well and we have had lots of very positive feedback from the demonstration days we’ve done.”

With a highly competitive atmosphere in the ski industry, both remain optimistic that their success will come from a similar model as independent craft brewers that went head-to-head with large breweries.

“There is a lot of potential for improved quality,” says Flowerday. “Ski technology has already changed so much in my lifetime and as more and more people take up backcountry skiing I think there will be a huge demand for innovation in those types of skis.”

Max Flowerday and Sam McEwan intend to be on the front line of this innovation.